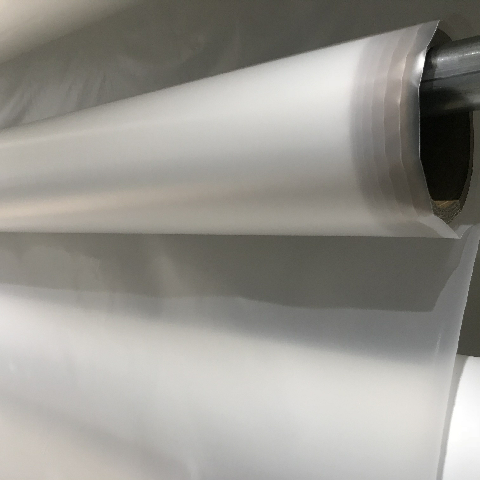

1. YintoniEVA Hot Melt Adhesive Film?

Yinto eqinileyo, i-thermoplastic adhesive material ebonelelwe ngefilimu encinci okanye ifom yewebhu.

Isiseko sayo sepolymer esisisekoI-Ethylene Vinyl Acetate (EVA)I-copolymer, ehlala idityaniswe kunye ne-resins, i-wax, i-stabilizers, kunye nezinye izilungisi.

Yenziwa isebenze bubushushu kunye noxinzelelo, ukunyibilika ukwenza iqhina elincamathelayo elomeleleyo xa lipholisa.

2. Iimpawu eziphambili:

Thermoplastic:Inyibilika xa ifudunyezwa kwaye iqine xa ipholisa.

I-Solvent-Free & Eco-Friendly:Ayinayo i-volatile organic compounds (VOCs), iyenza icoceke kwaye ikhuseleke kunezinto zokuncamathelisa ezisekwe kwi-solvent.

Ukudibanisa ngokukhawuleza:Ukuqalisa kunye nokudibanisa kwenzeka ngokukhawuleza xa kuthe kwafakwa ubushushu noxinzelelo.

Inyathelo lokuqala elilungileyo:Ibonelela ukubamba okuqinileyo kokuqala xa kunyibilikisiwe.

Ukuba bhetyebhetye:Iifilimu ezisekelwe kwi-EVA ngokubanzi zigcina ukuguquguquka okulungileyo emva kokubambisana, zihambelana kakuhle ne-substrates.

Uluhlu oluBanzi lokuncamathela:Iibhondi ngokufanelekileyo kwizinto ezahlukeneyo ze-porous kunye ne-non-porous (amalaphu, amagwebu, iiplastiki, iinkuni, isinyithi).

Ukuqhubekeka ngokulula:Iyahambelana ne-standard lamination ye-industrial kunye nezixhobo zokudibanisa.

Isebenza kakuhle emalini:Ngokubanzi isisombululo sokuncamathelisa esinexabiso eliphantsi xa kuthelekiswa nezinye iintlobo ze-HMAM (njenge-PA, TPU).

3. Izicelo eziphambili:

Ilaphu kunye nesinxibo:

Amalaphu okulamisa (umzekelo, ii-interlinings zeekhola, ii-cuffs, amabhanti esinqeni).

I-hemming kunye nokutywinwa kwe-seam.

Ukuncamathisela ii-appliqués, iipetshi, kunye neelebhile.

Ukudibanisa amalaphu angalukwanga (umzekelo, kwiimveliso zococeko, izihluzi).

Izinto zokubopha izihlangu ezinje ngeenzwane, izinto zokubala, ii-insoles, kunye nelinen.

Ukuqhoboshela phezulu kwi-midsoles okanye i-outsoles (ngokuphindaphindiweyo ngokudibanisa nezinye izinto zokunamathela).

I-Laminating yesikhumba sokwenziwa kunye neempahla.

Ukupakishwa:

I-Special Packaging Lamination (umzekelo, iphepha/ifoyile, iphepha/iplastiki).

Iibhokisi zokutywina kunye neebhokisi.

Ukwenza iibhokisi eziqinileyo.

Iimoto & nezoThutho:

I-Bonding yangaphakathi ye-trim components (i-headliners, iipaneli zomnyango, iikhaphethi, ii-trunk liners).

Amalaphu okuhlamba amagwebu okanye ama-composites.

Ibhanti yomda kunye nokutywinwa.

Ifenitshala kunye neUpholstery:

Ukudibanisa ilaphu kwi-foam padding.

Ukutywinwa komphetho kunye ne-lamination kumatrasi kunye ne-cushions.

I-Laminating imiphezulu yokuhlobisa.

Izilaphu zobuGcisa kunye neeLaminates zoShishino:

Iimaleko zokudibanisa kwimidiya yokucoca.

Laminating geotextiles.

Ukudala imathiriyeli edibeneyo yokusetyenziswa kwemizi-mveliso eyahlukeneyo.

I-DIY kunye nemisebenzi yezandla:(Ukwahluka kwendawo enyibilikayo esezantsi)

Izinto zokudibanisa kwiiprojekthi zokuzilibazisa.

Ubugcisa belaphu kunye nokuhonjiswa.

4.UkusetyenzwaIindlela:

5.I-Flatbed Lamination:Ukusebenzisa oomatshini bokushicilela beplaten abashushu.

Ukunyibilikisa okuQhingayo:Ukusebenzisa iirola zekhalenda ezishushu okanye i-nip rollers.

Ukudityaniswa kweContour:Ukusebenzisa izixhobo ezikhethekileyo zokufudumeza kwiimilo ezithile.

I-Ultrasonic Activation:Ukusebenzisa amandla e-ultrasonic ukunyibilikisa ifilimu kwindawo (engaphantsi kwesiqhelo kwi-EVA kunezinye iintlobo).

Inkqubo:Beka ifilimu phakathi kwama-substrates -> Faka ubushushu (ukunyibilikisa ifilimu) -> Faka uxinzelelo (ukuqinisekisa ukudibanisa kunye nokumanzisa) -> Ukupholisa (ukuqinisa kunye nokwakhiwa kwebhondi).

6. Izinto eziluncedo ze-EVA HMAM:

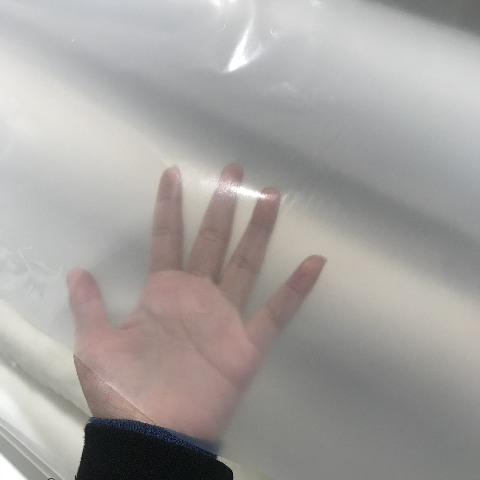

Icocekile kwaye kulula ukuyiphatha (akukho bumdaka, ayinathuli).

Ubunzima obuhambelanayo kunye nokusabalalisa okunamathelayo.

Akukho xesha lokumisa / lokunyanga elifunekayo emva kokudibanisa.

Uzinzo olugqwesileyo lokugcina phantsi kweemeko eziqhelekileyo.

Ibhalansi elungileyo yokubambelela, ukuguquguquka, kunye neendleko.

Amaqondo obushushu okusebenza aphantsi xa kuthelekiswa nezinye ii-HMAM.

6. Unyino/Iingqwalasela:

Uvakalelo lobushushu:Iibhondi zinokuthambisa okanye zingaphumeleli kumaqondo okushisa aphakamileyo (ngokuqhelekileyo anqunyelwe <~ 65-80 ° C / 150-175 ° F ngokuqhubekayo ukusetyenziswa, kuxhomekeke ekuqulunqweni).

Ukumelana neMichiza:Ngokuqhelekileyo ukunganyangeki kakuhle kwizinyibilikisi, ioyile, nemichiza eyomeleleyo.

NONENgaphantsi komthwalo oqhubekayo, ngakumbi kumaqondo obushushu aphezulu, iindawo ezibotshiweyo zinokurhubuluza (zikhubazeke kancinci).

Ukuxhathisa ukufuma:Ukusebenza kunokuguquguquka ngokuxhomekeke kuqulunqo; Ayinamanzi ngokwendalo njengeefilimu zePUR.

Ukuhambelana kweSubstrate:Ngelixa ububanzi, ukubambelela kwiiplastiki zamandla aphantsi kakhulu (njenge-PP, i-PE) zihlala zifuna unyango olungaphezulu okanye ukwakheka okuthe ngqo.

Isiphelo:

Ifilimu ye-EVA Hot Melt Adhesive sisisombululo esiguquguqukayo, esinexabiso elisebenzayo, kunye nesisebenziseka lula, kunye nesisombululo sokusebenzisana esisetyenziswa ngokubanzi kuwo wonke amalaphu, izihlangu, ukupakishwa, izinto zangaphakathi zeemoto, ifenitshala, kunye nokulahlwa kwemizi-mveliso. Amandla ayo aphambili alele kukulula kwayo ukusetyenzwa, ukuguquguquka okuhle, ukucofa okuqinileyo kokuqala, kunye nendalo engenazinyibilikisi. Ngelixa ubushushu bayo kunye nokumelana neekhemikhali kubeka imida ethile, ihlala ilukhetho olubalaseleyo lwezicelo apho ezi zinto zingabalulekanga kwaye ukusebenza kweendleko kubaluleke kakhulu.

Ixesha lokuposa: May-29-2025